LQ Group: Flexible options for the switchgear cabinet with the LQ assembly system

With its extended assembly system for the switchgear cabinet, LQ Mechatronic-Systeme GmbH has successfully developed a flexible alternative to conventional mounting systems for switchgear cabinets. Individual configurations are achieved on the basis of four standard elements. LQ customers can gain the benefits of a specially coordinated solution that is impressive because of the level of customisation and flexibility it offers. Apart from this, design costs are reduced considerably. The assembly system can be used in the switchgear cabinet or as an integral part of the machine, thus opening up a huge number of options.

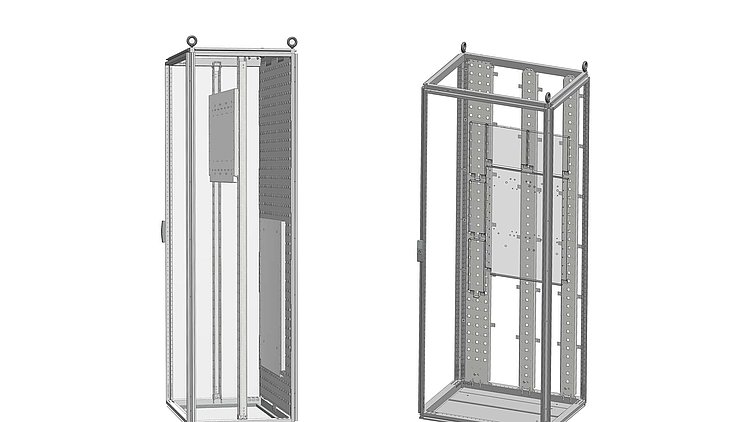

The LQ Group’s assembly system for switchgear cabinets has been developed on the basis of a modular system and now offers customers flexible solutions for assembly in the switchgear cabinet. LQ’s modular system contains all the mechanical elements that are required for mounting electromechanical functional units – the modules – in the switchgear cabinet. The system consists of four elements that can be used flexibly and on an individual basis.

To meet customers’ requirements

Individual components are assembled to form complete functional units and fitted on the mounting plates (1). There are different versions: with or without preshaped DIN rails, with or without perforations – designed entirely to suit the customers’ requirements. Their sizes also vary. The customer can choose a suitable model from a wide choice of variants and versions. The preshaped hooks provide a quick and easy way to fit the mounting plates, with the modules already fitted, to a large mounting plate (2) or mounting bars (3) in the switchgear cabinet. The mounting bars are a refinement by the LQ Group and provide an alternative to the conventional assembly plate. Depending on the customer’s requirement and the situation, either the large mounting plate or the single- or three-row assembly bars can be used. The U-shaped section (4) is another new element that can also be fitted to secure the mounting plates in the switchgear cabinet. However, it also provides greater flexibility: because it can be fitted at the side, it also allows further levels to be installed, depending on requirements. This means that less space is needed to install all the functional units required.

Individual and flexible

LQ customers benefit from greater flexibility and customisation, thanks to the extended assembly system. The elements in the design required are defined and assembled to form the overall system in accordance with the customer’s specific requirements. Even if the design of the switchgear cabinet is already complete, the cabinet can still be extended flexibly thanks to the modular system. Quite apart from this, the minimal design effort required is a factor in favour of the LQ Group’s system. The standardised elements make it considerably easier to design the interior of the switchgear cabinet.

The assembly system can also be adapted individually to suit the available space and the customer’s circumstances and integrated according to the situation: it is suitable for any size of switchgear cabinet or switchroom or as an integral part of the machine. It can also be secured to the wall. The assembly system offers many versatile possibilities.