Solution-partnership unites Siemens and LQ

German engineering expertise comes together at the highest level. It is not unusual for supposed competitors to combine their efforts to work on new solutions. Since it became known that several premium car manufacturers have forged these kinds of partnerships, they have become an accepted way for companies to work together.

It is not unusual for supposed competitors to combine their efforts to work on new solutions. Since it became known that several premium car manufacturers have forged these kinds of partnerships, they have become an accepted way for companies to work together. Both sides benefit from the expertise that the other party can bring to the table, and the customer is the overall winner, getting the best possible, top-quality product. So it's hardly surprising that Siemens has also been looking for the perfect sparring partners for complete power supply chain systems - and has found them in LQ Mechatronik-Systeme GmbH, based in Besigheim, Germany.

This partnership brings together the global positioning and targeted system solutions of Siemens with LQ’s technical expertise in power supply chain systems. It will bring clear benefits for customers, who will have one partner to look after all their needs - from design to development to service. Customers will be offered a targeted solution for their whole system, comprising top-quality power supply and control systems. The bottom line is that they will have to coordinate fewer suppliers and handle fewer purchase order items for each machine.

Power supply chains as a complete package

Power supply chains are needed wherever moving machine parts have to be supplied with power, data, liquids or gases. But not all power supply chains are the same. It is important to understand the characteristics of the individual components and to find the optimum position for cables and hoses in plastic housings. It is also necessary to consider the bend of the individual cables and the dynamics of the movement of the power supply chain system. Only then is it possible to create the appropriate overall system that will operate reliably over a long period.

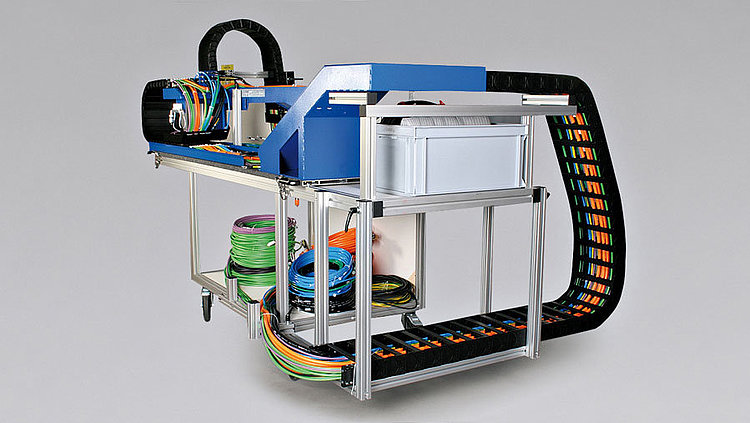

LQ Mechatronik-Systeme GmbH only start constructing the system once they have got to know their customer's machinery inside out. Working together with Siemens, the Besigheim-based company can now supply engineering and design from a single source. This includes the definition of components, interfaces and cable routing. The customer is supplied with a pre-assembled, 100% tested system that just has to be fitted to the machine. They no longer have to worry about every single cable that runs into the equipment, and they can save on warehousing costs as they no longer need to keep stocks of cables and carriers.

LQ are not only experts in configuring and installing cables within the system, but they also provide a top-quality logistics service. The ready-assembled power supply chains are delivered on transport racks appropriate to the particular machine, so that it is easy to integrate them into the existing machine layout. This means the customer's installation time is reduced from several days to just a few hours. And after installation, the 100% tested systems mean that machine downtime is greatly reduced. But if there should be any problems, the service team are available to help, 24 hours a day. At the end of this year, the mechatronics experts are planning to commission a state-of-the-art testing system in order to obtain reliable data on the operating life of their power supply chain systems. This will serve to cement still further their reputation as trusted suppliers.