Automation solutions from the LQ group Cable assembly, cable groups, cable chain systems and switchgear cabinets

High-quality cable assemblies are among the most important components in the field of mechanical and plant engineering for reliable and fault-free control of electrical systems. The LQ Group designs and manufactures complete electromechanical systems used for installation technology in mechanical and plant process engineering. We group together individual components for both control and machine installation to form compact functional units. Modular switchgear cabinets form the basis of automation on the control side. When we install plant and machinery the focus too is always on function and we supply top quality systems that are ready for installation.

Where do automation solutions make sense?

Automation solutions can be integrated into a wide variety of requirements and application areas. Initially very expensive and not very economical, automation was initially used primarily in industry for the production of large quantities. Nowadays, automation has an impact on many other areas. Thanks to the continuous development of technical procedures, robots, and processes, automation is now also possible for the production of small series. However, economic efficiency must always be taken into account. Automating complex processes in particular costs a lot of money. For this reason, it makes sense to invest in expensive robots and software, especially for frequently required steps in a production process. As a cheaper and more profitable option, many companies rely on partial automation of processes in combination with human labor.

The intelligent automation of the future

Artificial intelligence, robotics and IoT (Internet of Things) have accelerated automation further. From a company's point of view, the reasons for driving automation forward are primarily to increase productivity whilst at the same time reducing overall labour costs and maintaining constant and higher quality. It also allows processes to be organised more efficiently during production, thus saving additional costs.

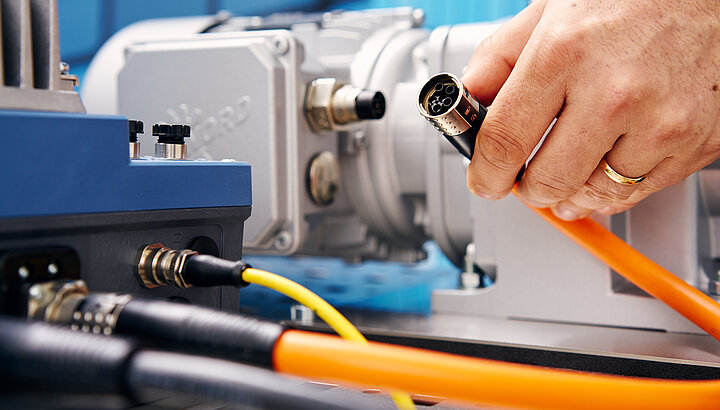

Cable assembly and cable groups

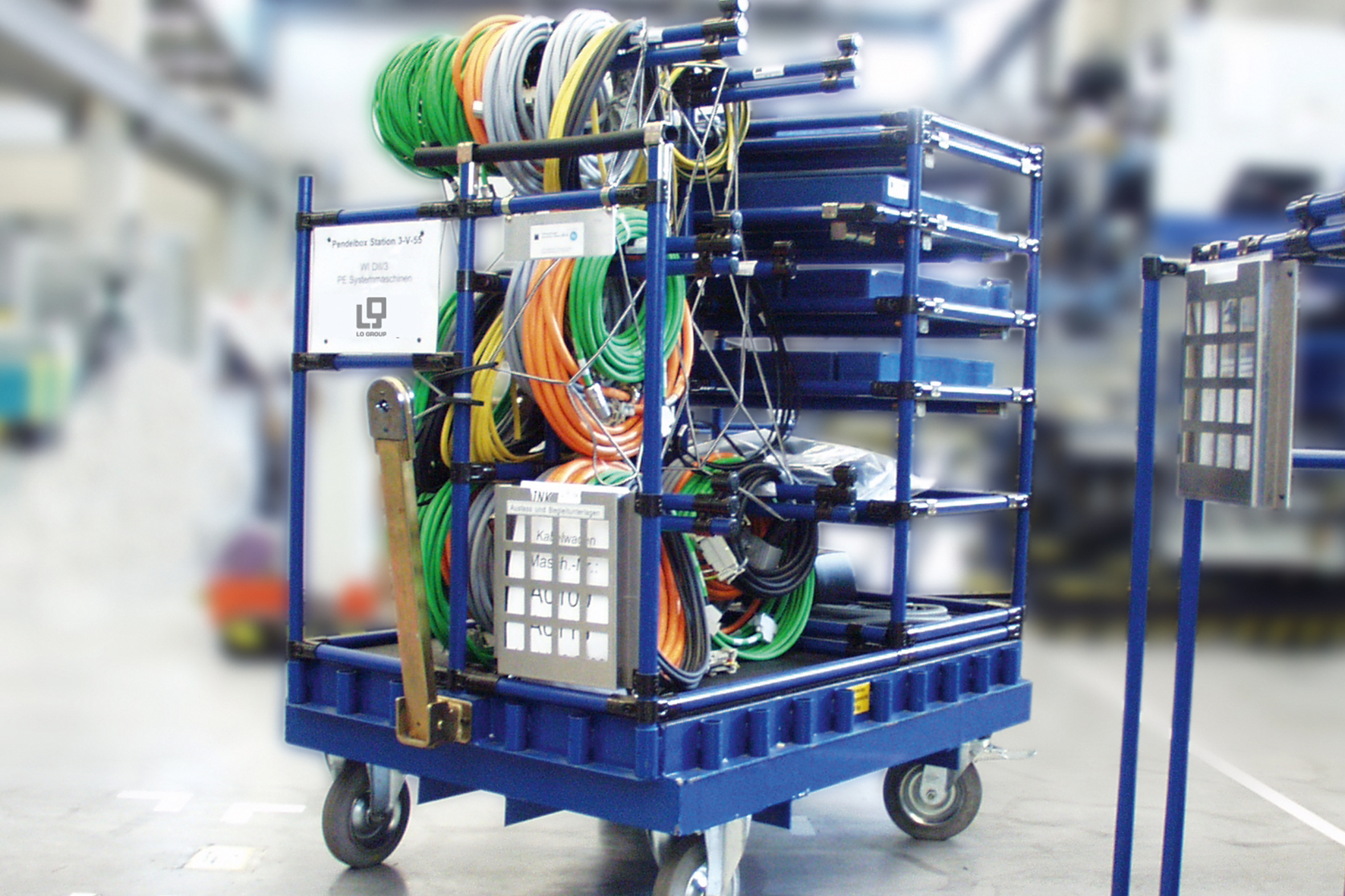

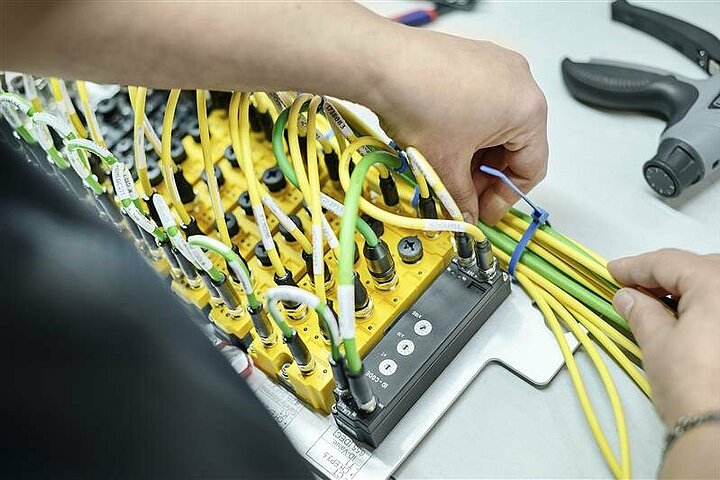

LQ ensures process-reliable provision of cable assembly and cable groups. We can supply cables with suitable round or square connectors of varying sizes, ranging from connector systems with M8 and M12 cables for 24 V applications, signal and power cables to servo and data cables. Apart from assembling individual cables, we produce customised cable groups. All assemblies are 100% checked to ensure that they function properly and are delivered on special transport racks with clear source and destination markings. Innovative programs and our extensive inspection procedures ensure that in-house order processing is of high quality.

Cable chain systems

LQ is an experienced systems partner when it comes to cable carrier design and installation and the company offers solutions for any application. Services range from simple pluggable chains to complex multi-axis systems and cable chain systems that cover distances of up to 40 metres. From verifying technical feasibility to project planning and production right through to delivery directly to our customers’ production lines, we offer a full service that is entirely tailored to how your machines are being operated. We offer punctual on-site delivery, just in sequence, ready-to-install systems, a 24-hour on-call service and fast deliveries of spare parts if machines are down.

Modular switchgear cabinet construction

Depending on what the customer requires, as service providers we design both conventional and modular switchgear cabinets. This modular concept has allowed LQ to revolutionise the way switchgear cabinets are structured. We group individual components to create functional assemblies and thus replace individual wiring systems, which are more complex. Perfection is achieved with switchgear cabinets that are less complex to build, thus reducing both the number of different parts required and assembly throughput times considerably.

Interesting facts about system suppliers

Here you will find further information on the topic of system suppliers:

Services offered by a system supplier

The importance of flexibility and agility for system supplier

The importance of innovation partnerships for system suppliers

The importance of quality assurance for system suppliers

The role of a system supplier in the value chain

The future of the system supplier concept

Success factors for system supplier

Global challenges and opportunities for system suppliers

Fundamentals of the system supplier concept

Challenges in integrating system suppliers into business processes

Customization of products by system suppliers

Cost management strategies for system suppliers

Customer relationship management for system suppliers

Logistics and supply chain management for system suppliers

Strategies for selecting and evaluating system suppliers

Strategies for diversifying the product range of system suppliers

Advantages of working with a system supplier

Competitive situation and strategies in the system supplier industry

Your contact