Cable chain systems from LQ You provide the specification, we provide the solution

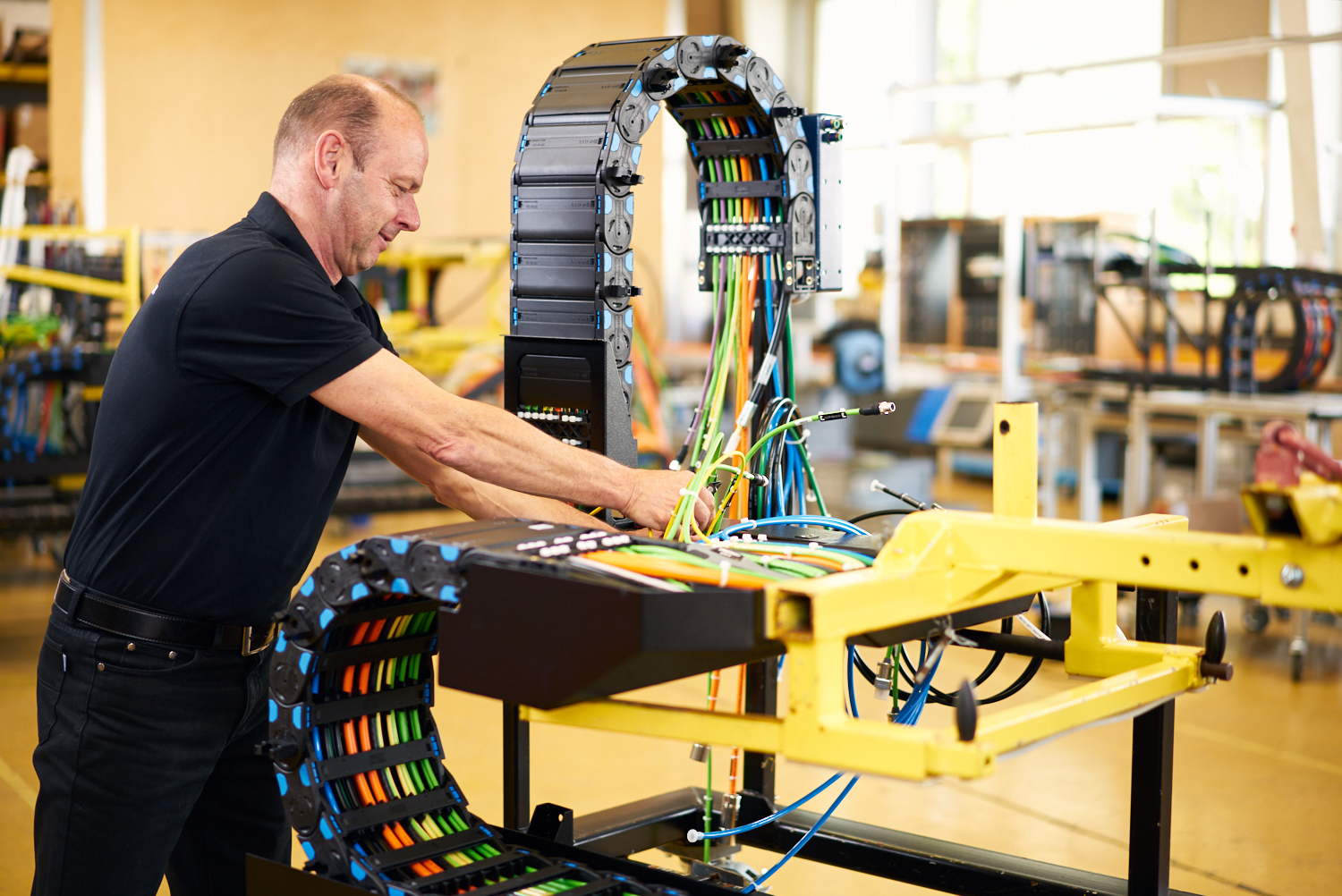

The production of complete, ready-to-assemble cable chain systems is one of our core competencies. On request, we organize everything from engineering, assembly, shipping on adapted transport racks, to comprehensive service. Whether for simple standardized energy chains or for complex systems with up to 40 meters of travel. Cable chain systems are used wherever moving machine parts have to be supplied with energy or data. The analysis and project planning of these complex products are at least as important to us as advice on the use of components such as high-quality connectors, cables or hoses. As a system partner, we organize all details of machine installation, take care of manufacturers and suppliers, and provide complete, ready-to-install cable chain systems, including installation plans.

Individual design of cable chain systems From prototype to complete system

On behalf of the customer, we develop prototypes and support the introduction or conversion to new components and assemblies. All project data can be managed and updated centrally via an engineering tool. We take responsibility for providing standard, simple cable chain systems and also organize everything for complex solutions, from cable assembly to the complete system. This creates enormous advantages in terms of quality, time and costs.

Simple, pluggable cable chain systems and multi-axis systems System solutions from LQ

Depending on the application, drag chains turn out very differently. Cable chain systems with plastic or metal rods are recommended depending on the environmental conditions or load. The dynamics of the equipped chains at the later place of use also play a role in the selection of components, because cables and plastic parts last differently depending on the stress.

When it comes to placement, our assembly staff takes great care in laying the individual cables in the chain. Finally, all our Cable chain systems are professionally strain-relieved and tested one hundred percent for optimal functionality.

We will not let you down The 24-hour on-call service from LQ

Trained LQ employees take care of maintenance, service work, repairs and spare parts procurement for the complete systems supplied. Conversions and commissioning are also carried out worldwide on request thanks to a 24-hour on-call service. The custom-fit installations are provided just in sequence.

Cable chain systems from LQ in use Reference projects

CHIRON Multi-axis chain Installation of multi-axis drag chains in the assembly cycle

For Chiron-Werke GmbH & Co. KG we assemble and supply, among other things, complex, three-dimensional X/Y/Z Cable carrier system combinations. Our W-TEC power cables are the first choice for the assignment of drag chains, as they are available in high quality for a wide range of applications. The "marriage" of the control cabinet and installation technology takes place in advance at our factory. The project entry of all components is realized directly into the assembly cycle during ongoing series production.

INDEX TRAUB TNL32 Cable chain systems according to parts list specifications

For Index Traub GmbH, we assemble Cable chain systems according to the customer's exact parts list specifications and deliver them to the existing series in the shortest possible time - plug & play in less than an hour. Specially developed transport racks facilitate the handling of the bulky drag chains and protect them until installation.

TRUMPF TruLaser 5030 Ready-to-install multi-axis chain combinations for machine tools

For machine tools of TRUMPF GmbH + Co. KG, we assemble complex three-axis combinations with Cable chain systems that can be plugged in at both ends, according to the customer's exact parts list specifications. The mechatronic units are delivered to the customer ready for installation on special multi-way shuttle frames.

Advantages of LQ cable chain systems

- Experts in preassembled chains for over 20 years

- 24/7 on-call service: From the selection of the suitable raw cable to the cable assembly and the finished drag chain.

- Individual productions on customer request possible → we create the suitable chain for the respective application

- Plug&Play: Delivery of ready-to-install systems

- Pre-assembled energy chains reduce manufacturing costs, logistics effort and assembly times

- Reduction of downtimes and extension of the service life of lines and hoses through protection against external influences

Interesting facts about cable chain systems

Cable chain systems are machine components used for the energy supply of machine tools. They are used to safely guide flexible cables and pneumatic as well as hydraulic hoses. The cable chain systems protect cables from external influences and ensure a longer service life. Without the cable guide, the cables could move uncontrollably and wear out faster. Cable chain systems are flexible and mostly made of robust plastic and thus designed for frequent movement.

Functional principle, areas of application and selection of cable chain systems

There are many different designs of cable chain systems. The material used is plastic or stainless steel. The chains are guided to the respective workplace as cable chain systems. Most of them have a rectangular shape in which the cables are guided. The individual chain links between the start and end pieces can be opened individually to provide access to each cable as needed. To prevent the cables from lying in the chain without a firm hold, there are so-called stays that separate them from each other. At the beginning and end of the chain, the hoses and cables are clamped with the aid of cable ties or clamps, thereby relieving strain. In this way, no cable can slip and they remain in place. The cable chain systems are divided into unsupported, suspended, standing and gliding.

Unsupported energy chain: If the upper run, i.e. the part of the energy chain guided at the top, does not touch the lower run, it is called an unsupported energy chain. The unsupported energy chain is the most common design for high dynamic loads and long service life.

Suspended energy chain: Suspended energy chains are used when the radius curve hangs downwards with vertical direction of movement.

Standing energy chain: Energy chains whose radius bend is upwards with vertical direction of movement are referred to as standing energy chains.

Gliding energy chain: In gliding energy chains, the upper run glides on the lower run during the travel. A gliding chain is mostly used when long travels are required.

In mechanical engineering, a lot of things are in motion and therefore pose quite a challenge for cables and hoses. In order to be able to protect them from various impacts such as shocks and sparks, energy chains are used. They are used wherever moving electrical components or large machine parts have to be supplied with energy, electricity, liquids such as oil, air and also gases. Energy chains are used for machine tools (e.g. lathes, milling machines, bending machines, laser machines, punching machines), industrial robots, elevators or operating devices for cranes.

The selection of an cable chain systems is based on various factors that must be taken into account. The prerequisites must be coordinated in advance with the development by the customer.

- The course of movement (What kind of movement?)

- The installation conditions (How much space is available?)

- Application-specific environmental influences (e.g. chips, oil, moisture, chemicals)

- The cable laying must be measured (number and diameter, cable weight of the laid cables and hoses, necessary minimum bending radius).

- Is additional protection needed?